Personlized Products Low Viscosity Epoxy Resin - Good pigment wetting Epoxy Acrylate:HE3219 – Haohui

Personlized Products Low Viscosity Epoxy Resin - Good pigment wetting Epoxy Acrylate:HE3219 – Haohui Detail:

HE3219 is a 2-official modified epoxy acrylate oligomer, which has the characteristics of fast curing speed, good flexibility, good anti explosion performance, good wettability of pigment, good fluidity, high gloss and good balance of ink and water. It is especially suitable for UV offset ink, screen ink, vacuum electroplating primer

|

Item Code |

HE3219 |

|

|

Product features |

Fast curing speed Good flexibility Good pigment wetting |

|

|

Recommended use |

Offset ink |

|

|

Specifications |

Functionality (theoretical) |

2 |

|

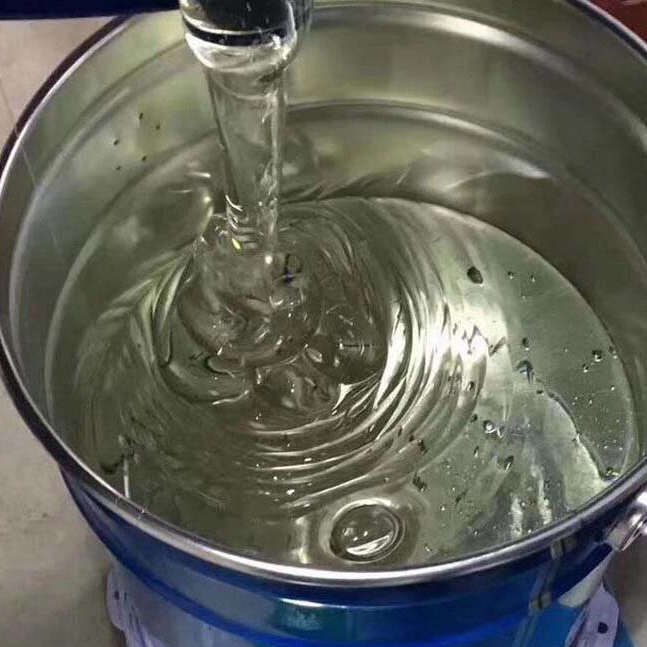

Appearance(By vision) |

Clear liquid |

|

|

Viscosity(CPS/60℃) |

3400-7000 | |

| Color(Gardner) |

≤4 |

|

|

Efficient content(%) |

100 |

|

|

Packing |

Net weight 50KG plastic bucket and net weight 200KG iron drum |

|

|

Storage conditions |

Please keep cool or dry place, and avoid sun and heat; |

|

|

Use matters |

Avoid touching the skin and clothing, wear protective gloves when handling; |

|

Guangdong Haohui New Materials CO , Ltd . established in 2009 , is a high-techenterprise focusing on the R & D and manufacturing of UV curable resin andoligomerHaohui headquarters and R & D center are located in Songshan lake high-techpark , Dongguan city . Now we has 15 invention patents and 12 practical patentswith an industry-leading high efficiency R & D team of more than 20 people , including I Doctor and many masters , we can provide a wide range of UV curablespecial acry late polymer products and high performance UV curable customizedsolutionsOur production base is located in the chemical industrial park – Nanxiong finechemical park , with a production area of about 20,000 square meters and anannual capacity of more than 30,000 tons . Haohui has passed the ISO9001 quality management system and ISO14001 environmental management system certification , we can offer customers good service of customization , warehousingand logistics

1. Over 11 years manufacturing experience , R & D team more than 30 people , we can helpour customer develop and produce high quality products .

2. Our factory has passed IS09001 and IS014001 system certification , ” good quality controlzero risk ” to cooperate with our customers.

3. With high production capacity and large procurement volume , Share competitive pricewith customers

1) Are you a factory or trading company ?

A: We are a professional manufacturer with over 11 years producing experience and 5 years exporting experience.

2) How long is the validity period of the product

A: 1 year

3) How about the company’s new product development

A: We have a strong R&D team, which not only continuously updates products according to market demand, but also develops products customized according to customer needs.

4) What are the advantages of UV oligomers?

A: Environmental protection, low energy consumption, high efficiency

5) lead time?

A: Sample needs 7-10 days, mass production time needs 1-2 weeks for inspection and customs declaration.

Product detail pictures:

Related Product Guide:

We'll make every effort and hard work being outstanding and excellent, and speed up our techniques for standing during the rank of global top-grade and high-tech enterprises for Personlized Products Low Viscosity Epoxy Resin - Good pigment wetting Epoxy Acrylate:HE3219 – Haohui , The product will supply to all over the world, such as: Azerbaijan, Bogota, Birmingham, Our products have enjoyed a great reputation for their good quality, competitive prices and prompt shipment in international market. Presently, we are sincerely looking forward to cooperating with more overseas customers based on mutual benefits.

The company comply with the contract strict, a very reputable manufacturers, worthy a long-term cooperation.