Nearly a decade after their introduction, UV LED curable inks are being adopted at an accelerated pace by label converters. The ink’s benefits over ‘conventional’ mercury UV inks – better and faster curing, improved sustainability and lower running costs – are becoming more widely understood. Additionally, the technology is becoming more easily accessible as press manufacturers offer to include a wider range of long-life lamps on their lines.

Moreover, there is a greater incentive for converters to consider switching to LED, because the risks and costs of doing so are reducing. This is being facilitated by the arrival of a new generation of ‘dual cure’ inks and coatings that can be run under both LED and mercury lamps, allowing converters to adopt the technology in steps, rather than abruptly.

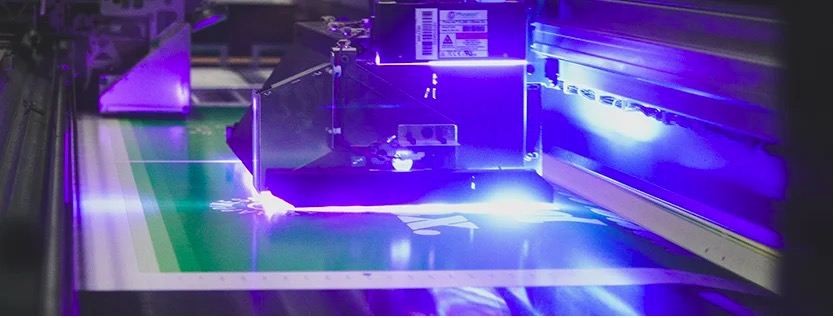

The main difference between a conventional mercury lamp and an LED lamp is the wavelengths emitted for curing to take place. The mercury-vapor lamp radiates energy across a spectrum between 220 and 400 nanometers (nm), while LED lamps have a narrower wavelength between about 375nm and 410nm and peaking at around 395nm.

UV LED inks are cured in the same way as conventional UV inks, but are sensitive to a narrow wavelength of light. They differ from each other, therefore, by the group of photoinitiators used to initiate the curing reaction; the pigments, oligomers and monomers used are the same.

UV LED curing offers strong environmental, quality, and safety advantages over conventional curing. The process uses no mercury or ozone, so no extraction system is needed to remove ozone from around the printing press.

It offers long-term efficiencies too. The LED lamp can be turned on and off with no need for warm-up or cool-down time, providing optimum performance from the moment it is switched on. There is no need for shutters to protect the substrate if the lamp is switched off.

Post time: Sep-07-2024