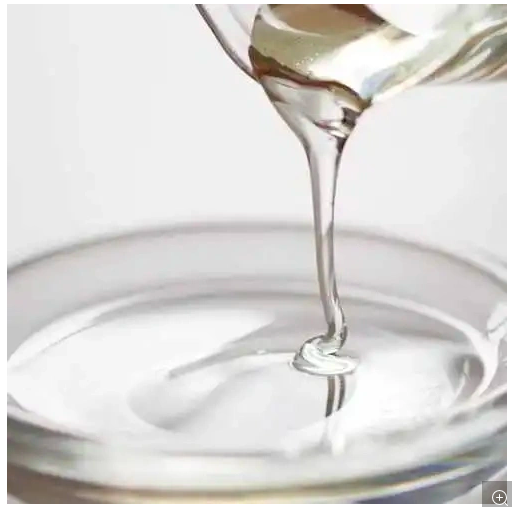

Vat photopolymerization, specifically laser stereolithography or SL/SLA, was the first 3D printing technology on the market. Chuck Hull invented it in 1984, patented it in 1986, and founded 3D Systems. The process uses a laser beam to polymerize a photoactive monomer material in a vat. The photopolymerized (cured) layers adhere to a build plate that moves up or down depending on the hardware, allowing successive layers to form. SLA systems can also produce very small and precise parts using a small laser beam diameter, in a process known as micro SLA or µSLA. They can also produce very large parts using a larger beam diameter and longer production times, within build volumes measuring over two cubic meters.

The SLA-1 Stereolithography (SLA) printer, the first commercial 3D printer, was introduced by 3D Systems in 1987.

There are several variations of vat photopolymerization technology available today. The first to emerge after SLA was DLP (Digital Light Processing), developed by Texas Instruments and brought to market in 1987. Instead of using a laser beam for photopolymerization, DLP technology uses a digital light projector (similar to a standard TV projector). This makes it faster than SLA, as it can photopolymerize a whole layer of the object at once (referred to as a “planar” process). However, the quality of the parts depends on the projector’s resolution and degrades as the size increases.

Like material extrusion, stereolithography became more accessible with the availability of low-cost systems. The first low-cost systems were based on the original SLA and DLP processes. However, in recent years, a new generation of ultra-low-cost, compact systems based on LED/LCD light sources has emerged. The next evolution of vat photopolymerization is known as “continuous” or “layerless” photopolymerization, which is typically based on a DLP architecture. These processes utilize a membrane, typically oxygen, to enable faster and continuous production rates. The patent for this type of stereolithography was first registered in 2006 by EnvisionTEC, a DLP company that has since been rebranded as ETEC, following its acquisition by Desktop Metal. However, Carbon, a Silicon Valley-based company, was the first to market this technology in 2016 and has since established itself as a leader in the market. Carbon’s technology, known as DLS (Digital Light Synthesis), offers significantly higher productivity rates and the ability to produce parts with durable hybrid materials, combining thermosets and photopolymers. Other companies, such as 3D Systems (Figure 4), Origin (now part of Stratasys), LuxCreo, Carima, and others, have also introduced similar technologies to the market.

Post time: Mar-29-2025