New Arrival China A Full Acrylic Oligomer - Good flexibility Epoxy Acrylate :CR91192 – Haohui

New Arrival China A Full Acrylic Oligomer - Good flexibility Epoxy Acrylate :CR91192 – Haohui Detail:

CR91192 is a special modified epoxy acrylate oligomer. It has good adhesion on glass and some difficult-to-attach substrates. It can be widely used in glass and metal coatings

|

Item Code |

CR91192 |

|

|

Product features |

Good flexibility Good adhesion |

|

|

Recommended use |

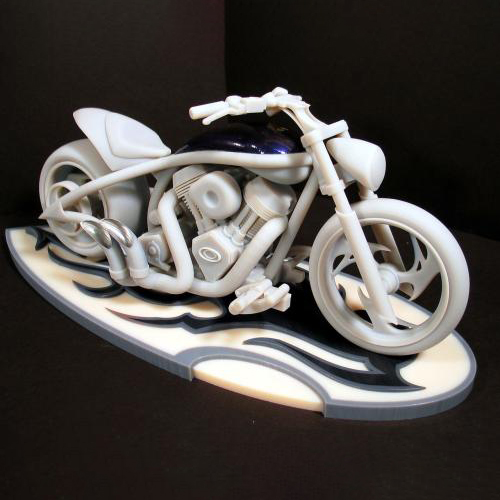

Glass and ceramic coatings Metal coating Inks Difficult to adhesion substrate treatment agent |

|

|

Specifications |

Functionality (theoretical) |

2 |

|

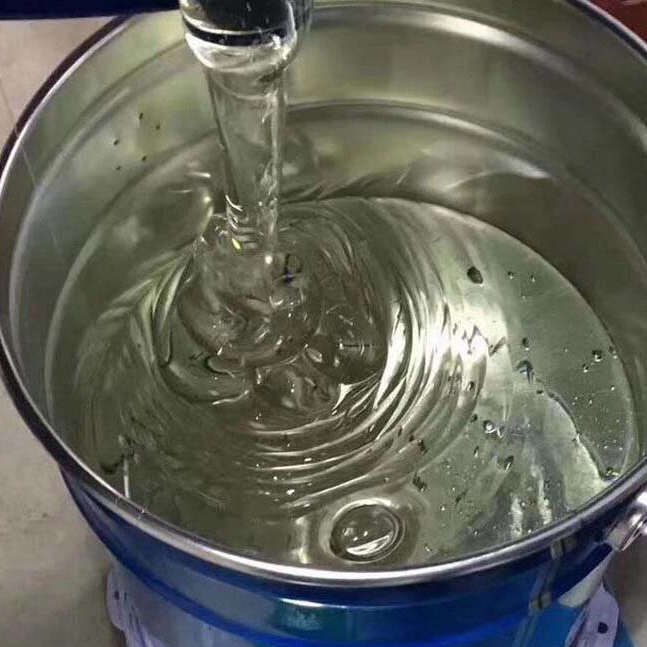

Appearance(By vision) |

Yellowish liquid

|

|

|

Viscosity(CPS/25℃) |

10000-20000 | |

|

Color(APHA) |

≤500 |

|

|

Efficient content(%) |

100 |

|

|

Packing |

Net weight 50KG plastic bucket and net weight 200KG iron drum

|

|

|

Storage conditions |

Please keep cool or dry place, and avoid sun and heat;

|

|

|

Use matters |

Avoid touching the skin and clothing, wear protective gloves when handling; |

|

Guangdong Haohui New Materials CO , Ltd . established in 2009 , is a high-techenterprise focusing on the R & D and manufacturing of UV curable resin andoligomerHaohui headquarters and R & D center are located in Songshan lake high-techpark , Dongguan city . Now we has 15 invention patents and 12 practical patentswith an industry-leading high efficiency R & D team of more than 20 people , including I Doctor and many masters , we can provide a wide range of UV curablespecial acry late polymer products and high performance UV curable customizedsolutionsOur production base is located in the chemical industrial park – Nanxiong finechemical park , with a production area of about 20,000 square meters and anannual capacity of more than 30,000 tons . Haohui has passed the ISO9001 quality management system and ISO14001 environmental management system certification , we can offer customers good service of customization , warehousingand logistics

1. Over 11 years manufacturing experience , R & D team more than 30 people , we can helpour customer develop and produce high quality products .

2. Our factory has passed IS09001 and IS014001 system certification , ” good quality controlzero risk ” to cooperate with our customers.

3. With high production capacity and large procurement volume , Share competitive pricewith customers

1) Are you a factory or trading company ?

A: We are a professional manufacturer with over 11 years producing experience and 5 years exporting experience.

2) How long is the validity period of the product

A: 1 year

3) How about the company’s new product development

A: We have a strong R&D team, which not only continuously updates products according to market demand, but also develops products customized according to customer needs.

4) What are the advantages of UV oligomers?

A: Environmental protection, low energy consumption, high efficiency

5) lead time?

A: Sample needs 7-10 days, mass production time needs 1-2 weeks for inspection and customs declaration.

Product detail pictures:

Related Product Guide:

We pursue the administration tenet of "Quality is exceptional, Provider is supreme, Name is first", and will sincerely create and share success with all clientele for New Arrival China A Full Acrylic Oligomer - Good flexibility Epoxy Acrylate :CR91192 – Haohui , The product will supply to all over the world, such as: Cannes, Panama, Yemen, Insisting over the high-quality generation line management and prospects guide provider, we have made our resolution to offer our shoppers using the initially stage purchasing and soon after provider working experience. Preserving the prevailing helpful relations with our prospects, we even now innovate our product lists the many time to meet up with the brand new wants and stick to the latest trend of this business in Ahmedabad. We're ready to facial area the difficulties and make the transform to grasp many of the possibilities in international trade.

Reasonable price, good attitude of consultation, finally we achieve a win-win situation,a happy cooperation!